You are standing in a showroom, or perhaps browsing endless product pages online for vinyl windows. You see terms like “Vinyl,” “PVC,” “uPVC,” “Cellular PVC,” and “Virgin Vinyl.” The salesperson tells you one thing; the brochure tells you another. Confusion sets in. Are you buying a high-tech building material, or a cheap plastic frame that will warp next summer?

Here is the brutal truth: The industry is terrible at naming things.

As a structural engineering consultant who has analyzed window failures for over a decade, I am here to clear the fog. This guide isn’t just a definition list; it is a forensic deep dive into what actually matters—the chemistry, the reinforcement, and the engineering that keeps your home secure.

Executive Summary: The 30-Second Verdict

If you are in a rush, here is the only equation you need to remember to survive the sales pitch.

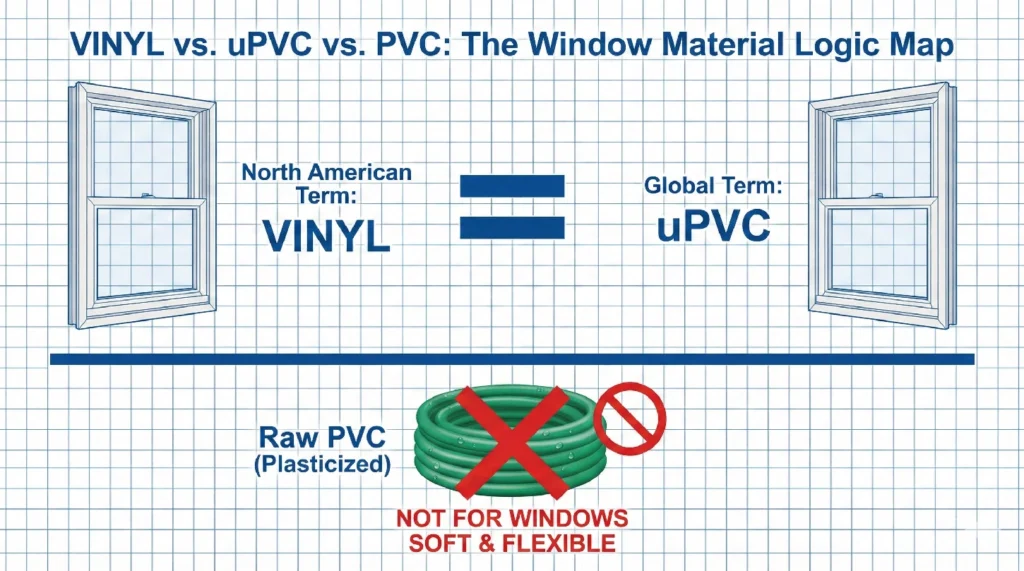

The Golden Rule: Vinyl Windows = uPVC Windows (In the US/Canada, we call it Vinyl. In Europe and the rest of the world, it is uPVC.)

The “PVC” Myth: If a contractor tries to sell you “PVC windows” as a superior, distinct alternative to “Vinyl,” they are technically incorrect. Raw PVC (Polyvinyl Chloride) is soft—think of a shower curtain or a garden hose. You cannot build a window out of it; the glass would crush the frame.

The Real Choice: You aren’t choosing between materials; you are choosing between Structural Engineering Methods:

Hollow Chamber uPVC (Standard Vinyl): The energy-efficiency champion.

Cellular PVC (Solid Core): The historical aesthetic champion.

The Chemistry: Why the "u" Matters More Than You Think

To understand why your windows won’t melt in the sun, we need to look at the molecular level. This distinction is the difference between a 20-year investment and a 2-year disaster.

The “Garden Hose” vs. The “Backbone”

PVC (Polyvinyl Chloride) in its native state is a rigid, brittle polymer. To make it useful for everyday items—like raincoats, electrical wire insulation, or garden hoses—manufacturers add chemicals called plasticizers (often phthalates). These plasticizers act like molecular lubricants, allowing the polymer chains to slide past each other.

uPVC (Unplasticized Polyvinyl Chloride) is what happens when we deliberately remove those plasticizers.

The Result: A material that is chemically “frozen” in a rigid state.

The Data: Standard PVC has a flexural modulus (stiffness) of roughly 400,000 psi. uPVC clocks in at nearly 360,000 to 450,000 psi but with vastly superior dimensional stability.

The Regional Dialect

Why the confusion?

Europe: Focused on technical accuracy, hence “uPVC.”

North America: Marketers felt “uPVC” sounded too chemical and industrial. “Vinyl” sounded smoother and more modern in the 1980s.

Key Takeaway: When you see a spec sheet for high-quality vinyl windows in Chicago or Toronto, the chemical composition is 100% uPVC.

The Real Market War: Hollow uPVC vs. Cellular PVC

Since we established that standard vinyl is uPVC, what are those expensive “Cellular” windows? This is the comparison that actually affects your wallet and your home’s curb appeal.

Option A: Standard Hollow Vinyl (The Efficiency King)

This is the modern standard. The profile is extruded with a hollow center, divided into multiple “chambers” (air pockets).

The Physics: Stationary air is an excellent insulator. By creating 5, 6, or even 7 separate chambers, the frame stops heat/cold transfer efficiently.

Best For: Maximizing energy savings (Lower U-Factor) and budget-conscious renovations.

Option B: Cellular PVC (The Wood Mimic)

This material is still uPVC, but it undergoes a micro-foaming process during extrusion. It captures millions of tiny air bubbles inside the plastic, creating a solid, dense material that feels exactly like wood.

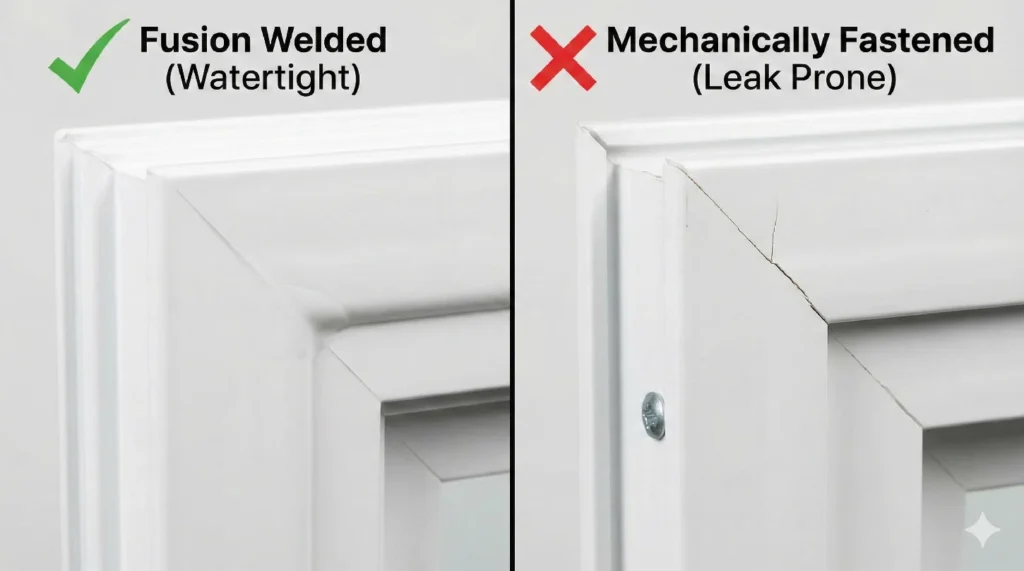

The Aesthetic: It can be cut, routed, and nailed just like cedar or pine. It typically features “mortise and tenon” joinery rather than welded corners.

Best For: Historical districts, homeowners who want to paint their windows, and high-end architectural designs.

Comparison Table: Which One Fits Your Project?

| Feature | Standard Hollow Vinyl (uPVC) | Cellular PVC (Solid Core) |

|---|---|---|

| Structure | Hollow, Multi-chambered | Solid, Micro-cellular foam |

| Corner Joint | Fusion Welded (Melted together) | Mechanically Fastened (Screws/Glue) |

| Insulation (R-Value) | ⭐⭐⭐⭐⭐ (Excellent) | ⭐⭐⭐⭐ (Good) |

| Maintenance | Zero (Never paint) | Low (Can be painted) |

| Look & Feel | Modern, Sleek, "Plastic" sheen | Traditional, Matte, "Wood" grain |

| Cost | $80-120(Moderate) | $180-220 (Premium) |

Engineering Deep Dive: What Makes a "Good" Vinyl Window?

This is where most homeowners get cheated. Two windows can look identical from five feet away, but one is a structural fortress, and the other is a flimsy shell. As an engineer, these are the three specs I demand to see.

1. Titanium Dioxide (TiO2): The “Sunscreen”

uPVC is naturally sensitive to UV radiation. Without protection, the sun will break down the polymer chains, causing the frame to turn yellow and become brittle (chalking).

The Standard: Premium American and European profiles use a proprietary blend containing 8-10 parts per 100 of high-grade Titanium Dioxide (TiO2).

The Risk: Cheap “builder-grade” windows often cut this to 2-3 parts.

Local Context: If you live in high-UV areas like Arizona, Florida, or Texas, inquiring about the TiO2 mix isn’t optional—it’s mandatory.

2. Wall Thickness & AAMA Ratings

Don’t just ask “Is it strong?” Ask “What is the wall thickness?”

Builder Grade: Typically 0.050 inches. These feel flimsy.

Premium Grade: 0.070 inches or thicker.

Authority Link: Check if the window meets the AAMA/FGIA 101 Standard for Performance Class. You want a rating of at least DP 35 (Design Pressure) for residential, or DP 50 for coastal areas. (Learn more at [FGIA Online])

3. Internal Reinforcement (The Steel Spine)

Plastic expands and is less rigid than aluminum. To compensate, large uPVC profiles must have a “skeleton.”

The Requirement: Look for Galvanized Steel or Aluminum reinforcement inserted into the central chambers of the frame. This structural rigidity is why uPVC is the standard material for complex, heavy-duty opening mechanisms found in Tilt and Turn Windows

The Test: If a window is wider than 36 inches and has no steel reinforcement, it is prone to bowing under high wind loads.

The Buying Guide: Your Showroom "Forensic Kit"

Don’t rely on the salesperson’s pitch. When you visit a showroom, bring these simple tools to perform your own quality control.

The Toolkit:

A High-Lumen Flashlight

A Strong Magnet

A White Sheet of Paper

Step-by-Step Inspection:

Step 1: The “Blue Tint” Test (Purity Check) Hold your white sheet of paper against the window frame.

Pass: The frame looks warm white, creamy, or matches the paper. This indicates Virgin Vinyl.

Fail: The frame has a distinct cool blue or greyish tint. This is a tell-tale sign of excessive “Regrind” (recycled factory scraps) or low TiO2 levels.

Step 2: The Magnet Test (Strength Check) Place your magnet against the vertical side (stile) of the sash, specifically near the locking mechanism.

Pass: The magnet sticks. This confirms there is steel reinforcement inside the chamber.

Fail: The magnet falls off. Unless it’s a very small bathroom window, walk away.

Step 3: The Weld Inspection (Waterproofing Check) Look closely at the 45-degree corner of the frame.

Pass: A “Fusion Weld.” It should look like the plastic was melted together into a single piece. It is watertight.

Fail: A “Mechanical Corner.” If you see a hairline crack or screws holding the corner together, this is a weak point that will eventually leak water into your wall.

Installation: The Hidden Killer of Vinyl

You can buy the most expensive vinyl windows in the world, but if installed incorrectly, they will fail within a year. Why? Thermal Expansion.

The Science of Movement

Vinyl has a high Coefficient of Thermal Expansion (approx. $70 \times 10^{-6} /K$).

Translation: Vinyl expands and contracts roughly 7 times more than glass and significantly more than wood or aluminum.

Real World Scenario: A 6-foot wide window can expand by over 1/4 inch on a hot July afternoon.

The “Jammed Sash” Syndrome

If your installer uses shims that are too tight or fails to leave a 1/4″ to 1/2″ gap between the window frame and the house studs (Rough Opening), the window has nowhere to expand.

Result: The frame bows inward.

Symptom: You suddenly can’t open or lock your window in the summer, but it works fine in the winter.

Pro Tip: Ask your installer specifically: “What size expansion gap are you leaving for the head and jambs?” If they say “None, we want a tight fit,” do not hire them.

Mistakes to Avoid & Troubleshooting

Mistake #1: The “Paint It Black” Disaster

We see this often. Homeowners want the modern farmhouse look and paint their white vinyl frames black.

The Physics: Black absorbs heat. Standard white vinyl is rated for about 140°F. Black paint can push surface temperatures over 170°F.

The Consequence: The frame warps permanently, and the glass seal fails (foggy glass).

Solution: Only buy factory-laminated black vinyl windows (using heat-reflective foils) or co-extruded acrylic capping.

Mistake #2: Caulking the Weep Holes

Look at the bottom exterior edge of your window. You will see small slots or holes.

Function: These are “weep holes.” They allow rain that hits the screen to drain out.

The Error: Homeowners or painters often caulk these shut, thinking they are air leaks.

The Result: Water gets trapped inside the frame, rotting the window from the inside out and damaging your subfloor.

Troubleshooting Guide

| Symptom | Probable Cause | The Fix |

|---|---|---|

| Condensation between glass | Failed IGU Seal | Replace the glass unit (not the whole frame). |

| Condensation on glass (inside) | High Indoor Humidity | Lower home humidity; check ventilation. |

| Sash is hard to slide | Dirty Track / Friction | Vacuum track. Lubricate with Silicone Spray (NOT WD-40!). |

| Drafts near the trim | Failed Exterior Caulk | Remove old caulk and re-seal with Polyurethane. |

Cost & ROI: Is High-End uPVC Worth It?

According to the 2024 Remodeling Impact Report by NAR (National Association of Realtors), replacing windows has a solid ROI, but strictly from a material standpoint, here is the breakdown:

Builder Grade Vinyl: ($200 – $400)

Verdict: False economy. You will likely replace them in 10-15 years due to seal failure or yellowing.

Premium Reinforced uPVC: ($600 – $1,200)

Verdict: The Sweet Spot. Lifespan of 25-35 years. High energy savings. Best balance of cost vs. performance.

Aluminum / Wood: ($1,500+)

Verdict: Aesthetic choice. Aluminum is stronger but colder (conductive). Wood is beautiful but requires high maintenance.

Frequently Asked Questions (FAQ)

-

1. Are PVC windows toxic to my family?

A: No. While the production of PVC involves harsh chemicals, the final rigid uPVC window product is stable and inert at ambient temperatures. It does not off-gas phthalates because, by definition (Unplasticized), it doesn't contain them.

-

2. Can I install vinyl windows myself?

A: I generally advise against it unless you are an experienced carpenter. The margin for error with waterproofing flashing and thermal expansion gaps is very small. A poor install ruins a great product. (See our guide: [How to Measure for Replacement Windows])

-

3. Why are European uPVC windows different?

A: European windows often use "Tilt and Turn" hardware with steel cores as standard. They are generally bulkier but higher performance than typical American single-hung vinyl windows.

-

4. Will vinyl windows support triple-pane glass?

A: Yes, but only if reinforced. Triple-pane glass is 33% heavier than double-pane. Ensure your quote specifies "Heavy Duty Sash Reinforcement" to prevent sagging.

Final Thoughts: Don't Guess on Quality

The battle between “Vinyl” and “PVC” is a linguistic distraction. The real battle is between Quality Engineering and Cheap Fillers.

Your windows are part of your home’s structural envelope. They protect you from wind, rain, and energy loss. Don’t settle for the cheapest quote. Use the Magnet Test, check the Weld, and demand AAMA Performance Specs.

If you need a quote from a Chinese door and window factory, please contact us.